What is Alkaline Hydrolysis?

In 2007 Resomation developed an award winning and patented design of an established technology that could for the first time be safely used to routinely and fully resolve a human body commercially to pure white ash.

The deceased person is delivered in a reusable wood casket to the Resomator unit where the deceased in the wool enclosure is transferred into the Resomator chamber. The system uses a water and alkali based method at high temperature and pressure to chemically reduce the body to white ash. After drying and processing of the white bones the pure white sterile ash is returned to the relatives just as with flame cremation. The process on average takes 3.5-4 hours.

Resomation believes that a temperature of 302°F/150°C is required to ensure pure white sterile ash is produced. The totally sealed pressurised chamber ensures that all bones and ultimately ash within the chamber are treated at sterilising temperatures to guarantee relatives of the deceased only get white sterile ash returned to them.

Basic Chemistry

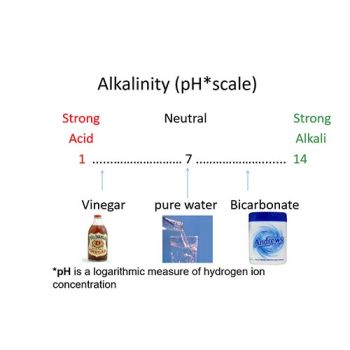

The pH scale above illustrates examples from the most acidic (pH1 ) to the most alkaline(pH 14). Resomation® starts off at around pH14 which is achieved in general terms with a mixture of 95% water and 5% liquid alkali (45% potassium hydroxide solution).

Other than the bones and the 60% water content, the remaining tissues in our body are all large complex macromolecules such as proteins, fats, carbohydrates and genetic material such as DNA.

These complex macromolecules are created during growth by a process of dehydration (water removal) to form strong chemical bonds linking various small building blocks millions of times to form long chains.

So, in essence, alkaline hydrolysis is a natural process.

This natural process is slow when occurring at low ambient temperatures. However chemical reactions can be massively accelerated by increasing the temperature and alkalinity. To increase the temperature of a liquid beyond its ambient boiling point, pressure is required to suppress boiling and allow the temperature to increase further.

So by increasing the alkalinity to pH14 using liquid potassium hydroxide and increasing the temperatures to 150°C/302°F, we can accelerate the same basic natural alkaline hydrolysis chemistry to achieve in 3-4 hours hours what nature achieves in months or years.

High versus Low Temperature

To achieve the level of ash purity that the family expect as in the picture above from Resomation, it is important that the process operates at a temperature of 302°F/150°C. Lower temperatures do not guarantee that the bones will be consistently white and sterile.

To achieve the cycle time comparable with flame cremation, it is necessary to operate at 302°F/150°C.

A key aspect of a sealed pressurised chamber operating at 302°F/150°C is that this allows both the air space above as well as the liquid itself to reach 302°F/150°C for at least one hour for effective sterilisation.

In low temperature (atmospheric pressure) systems the temperature is at best 93-98°C /200-208°F which is below sterilisation conditions especially in the air space above the liquid.

So when it comes to health and safety issues and obtaining sterile white ash every time, the need to operate at the temperature of 302°F/150°C is critical. In hospitals and pharmaceutical manufacturing of sterile liquids using heat temperatures of less than a minimum of 121°C (250°F) are never used to sterilise and for prions the recommendations are even higher from 134°C (280°F) to 150°C (302°F) depending on the application and local guidelines.